Page 15 - July24T

P. 15

gear/f lap speed (116) and do most everything abeam the numbers: Set power, carb heats on, get the flaps coming down, and lower gear. That is straightforward enough but with one caveat. The hydraulic f laps de- ploy slowly. Very slowly. So, by start- ing them down abeam the numbers, Welch’s preferred 20o-25o landing set- ting is not extended until late in the base leg. If full flaps (35o) are desired for a short-field landing, they won’t be down until established on final. Of course, this means lift/drag is a changing equation throughout almost the whole pattern, requiring careful attention to both power and airspeed. It’s a little distracting at first, but it’s manageable. Welch believes a future rebuild of the hydraulic pump will re- solve the slow-deployment issue. Once the chosen flaps are down, trim can be set for final approach speed, and things dial in quickly. Troy warned that pulling the power off too early, combined with a high flare, could set up an abrupt sink. But, honestly, I found the T-Nav to be a pussycat to land, providing honest pilot feedback

the whole time and with a sight picture that I felt comfortable with almost immediately.

In Gila Bend, Troy pumped just shy of 100 gallons into N108N as the temp hit its afternoon high of 93F. While we departed at least 400 pounds heavier than we had from CHD, the D-16A didn’t even seem to notice. It felt no different to me whatsoever. Of course, in a low-altitude engine-out scenario, I’m sure the differences would be no- table. Picking up our IFR clearance into Phoenix Sky Harbor Int’l (KPHX), we climbed to 7,000 feet. Level, we set 75% power, leaned via the EGTs, and settled into a 160 TAS cruise, burning 20 gallons per hour. Very economical, indeed. ATC requested 150 IAS throughout vectors onto the ILS at PHX. Since that’s 3mph below the yellow-line airspeed, descending into the afternoon turbulence was not a problem and hand flying was a breeze. Established on the LOC & GS for Runway 25L, we held 150 to a 3-mile final, then let the big props and the stiff headwind, followed by gear and flaps, slow us to Troy’s preferred

stabilized final speed of 100-105 (cross- ing the threshold at 90).

Before I’d even left the runway centerline, Troy was already answer- ing Tower’s questions about his Twin Navion. Taxiing onto the apron of Cut- ter Aviation, a single lineman guided us to parking. As both props stopped, three others materialized, all curious to know, “What is that?”

Matthew McDaniel is a Master & Gold Seal CFII, ATP, MEI, AGI, & IGI and Platinum CSIP. In 34 years of fly- ing, he has logged nearly 22,000 hours total and over 5,900 hours of instruction given. As owner of Progressive Avia- tion Services, LLC (www.progaviation. com), he has specialized in Technically Advanced Aircraft and Glass Cockpit instruction since 2001. McDaniel is also a Boeing 737-series Captain for an international airline, holds eight turbine aircraft type ratings, and has flown over 135 aircraft types. Matt is one of less than 15 instructors worldwide to have earned the Master CFI designation for 11 consecutive two-year terms. He can be reached at matt@progaviation. com or 414-339-4990.

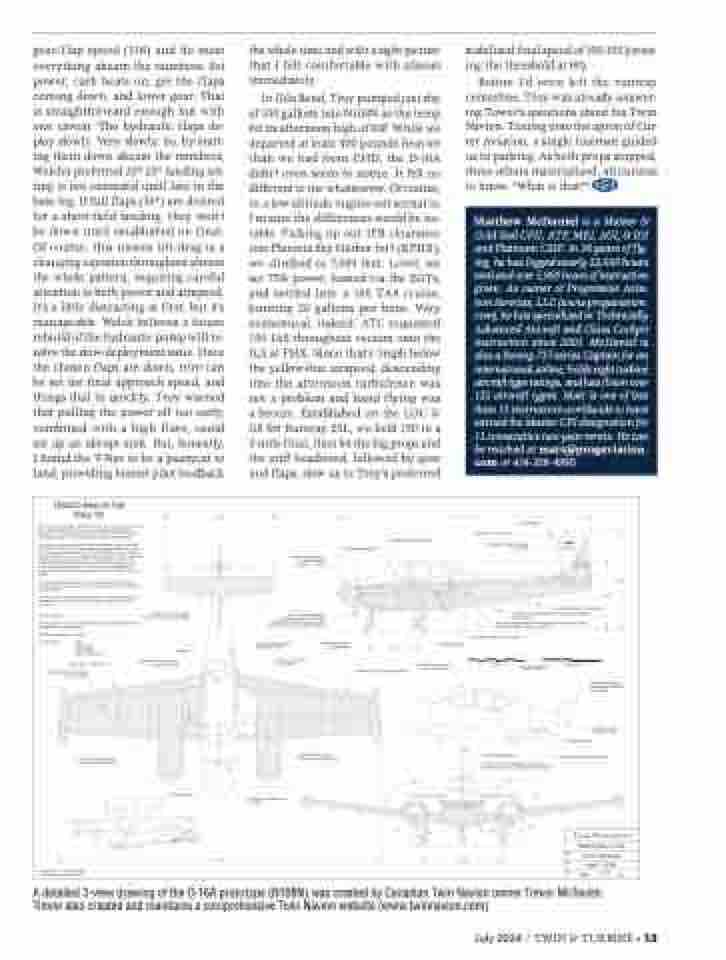

A detailed 3-view drawing of the D-16A prototype (N108N) was created by Canadian Twin Navion owner Trevor McTavish. Trevor also created and maintains a comprehensive Twin Navion website (www.twinnavion.com)

July 2024 / TWIN & TURBINE • 13